Designing in Scarcity

Saving the lingering piece…

October 2024 - December 2024

Process Design

Case Studies

Cuban Automotive

Since the 1960’s, Cuba has had a closed circulation of automotives imported from the United States. Due to a limited supply, the Cuban car scene sprung to be one of the most novel industries, bolstering repair, modification, and restoration of chasis manufactures over half a century ago.

Inventory

As a proof of concept, my project began with me digging in the scrap bin of my University woodshop. These are the parts I found:

Additional Step

Soviet Contraband Fashion

In the Soviet Union, imports were highly regulated. Traveling outside the Union was a very difficult task. Thus, contraband items became prized and sought after. One may consider Levi Jeans a standard in California, however abroad a pair was as precious as gold. With scarcity, the culture developed novel values in fashion, music, and all forms of art.

Congolese Chukudu

The Chukudu is a wooden scooter providing Congolese workers with jobs, and access to transportation. Made with wood, a machete and spare car parts, it is far more affordable and easier to construct than a manufactured truck. It may carry many bags of grain, wood, and any other resource under the drivers belly. The Chukudu has become a staple in the region.

Smaller non-congruent pieces.

Research

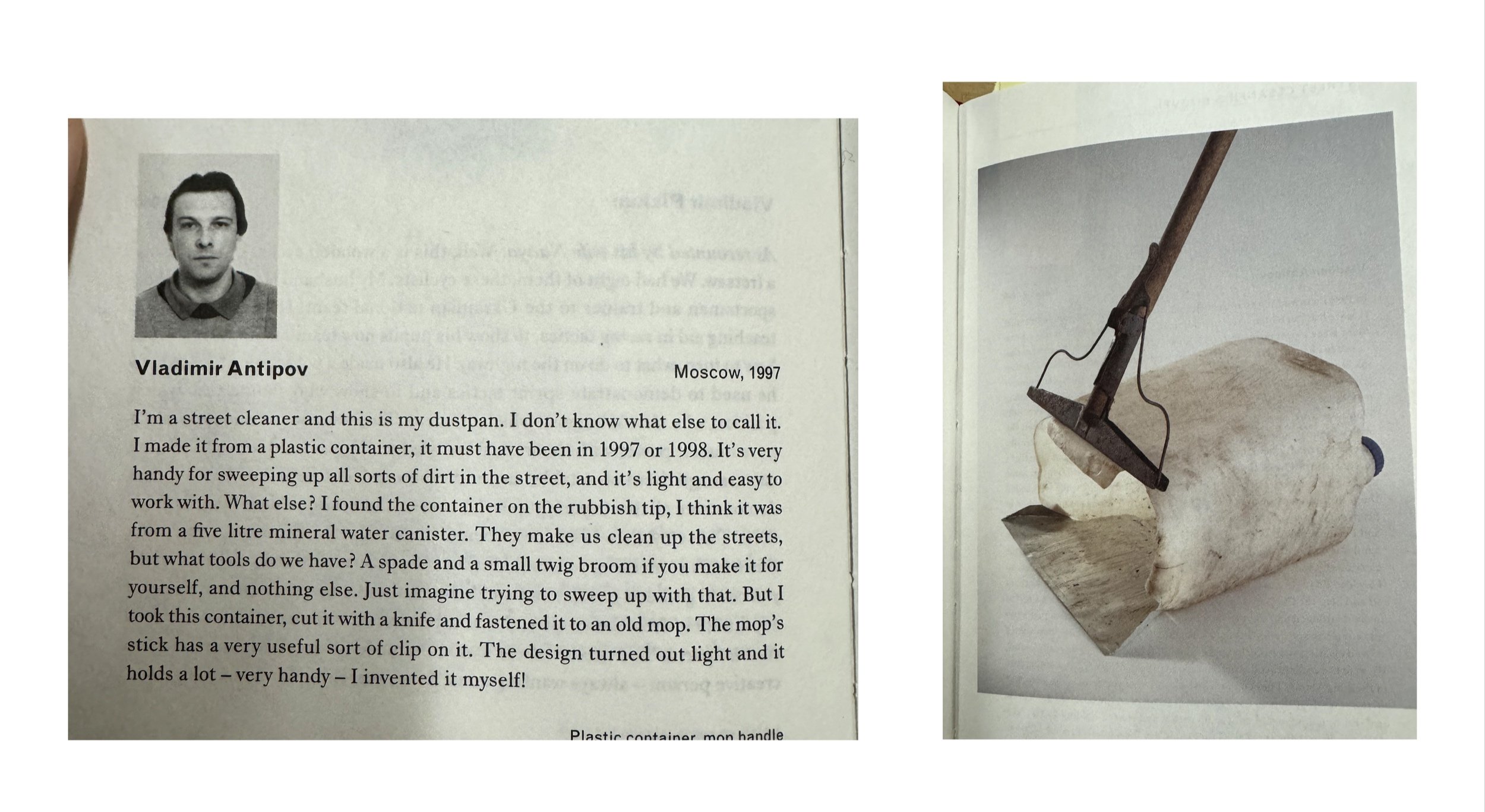

For this project, my professor recommended a book accounting Post-Soviet homemade utilities. The book resonated, brimming with like-minded projects.

Here are a few examples of my direction. In these projects, objects elevate their novelty — contrasting natural forms with solidity and structure.

The lightbulb, and the flat surfaces bring the raw material to life.

Conceptualize

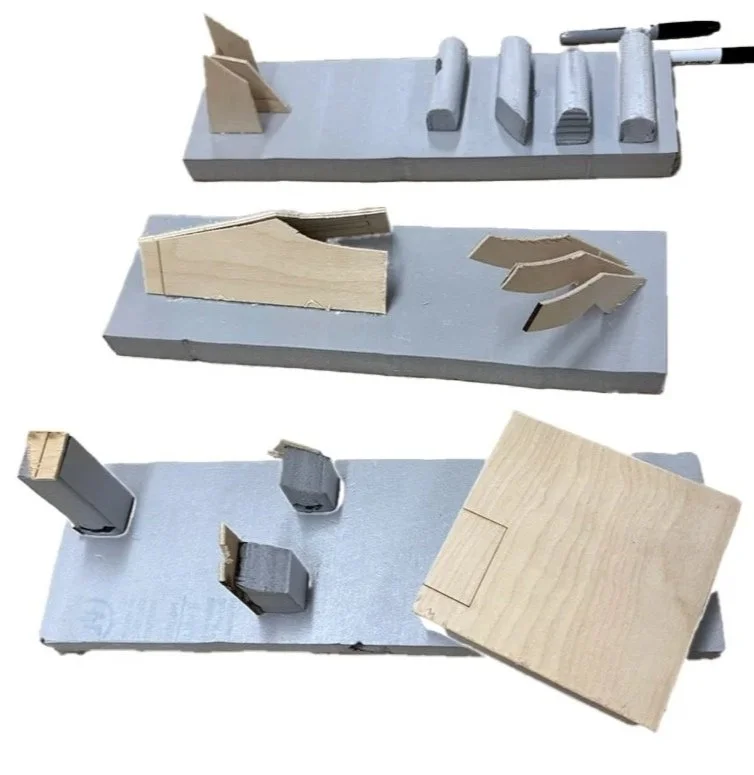

With additional scrap material, I explored the different applications for space and otherwise unusable parts.

1st row: Organizing unique parts.

Even though they are unique, a common denominator may be used to arrange for modular and organized structures: the wooden pieces all share a flat face, while the abbreviated foam pieces are all cylindrical.

2nd row: Utilizing unique facets.

. Here the differences and unique curves and edges allow for a structural support and novely that would otherwise be reason for discarding material.

3rd row: Perfection leads to waste.

This is a visual to represent how exclusively utilizing perfected forms lead to unusable potential

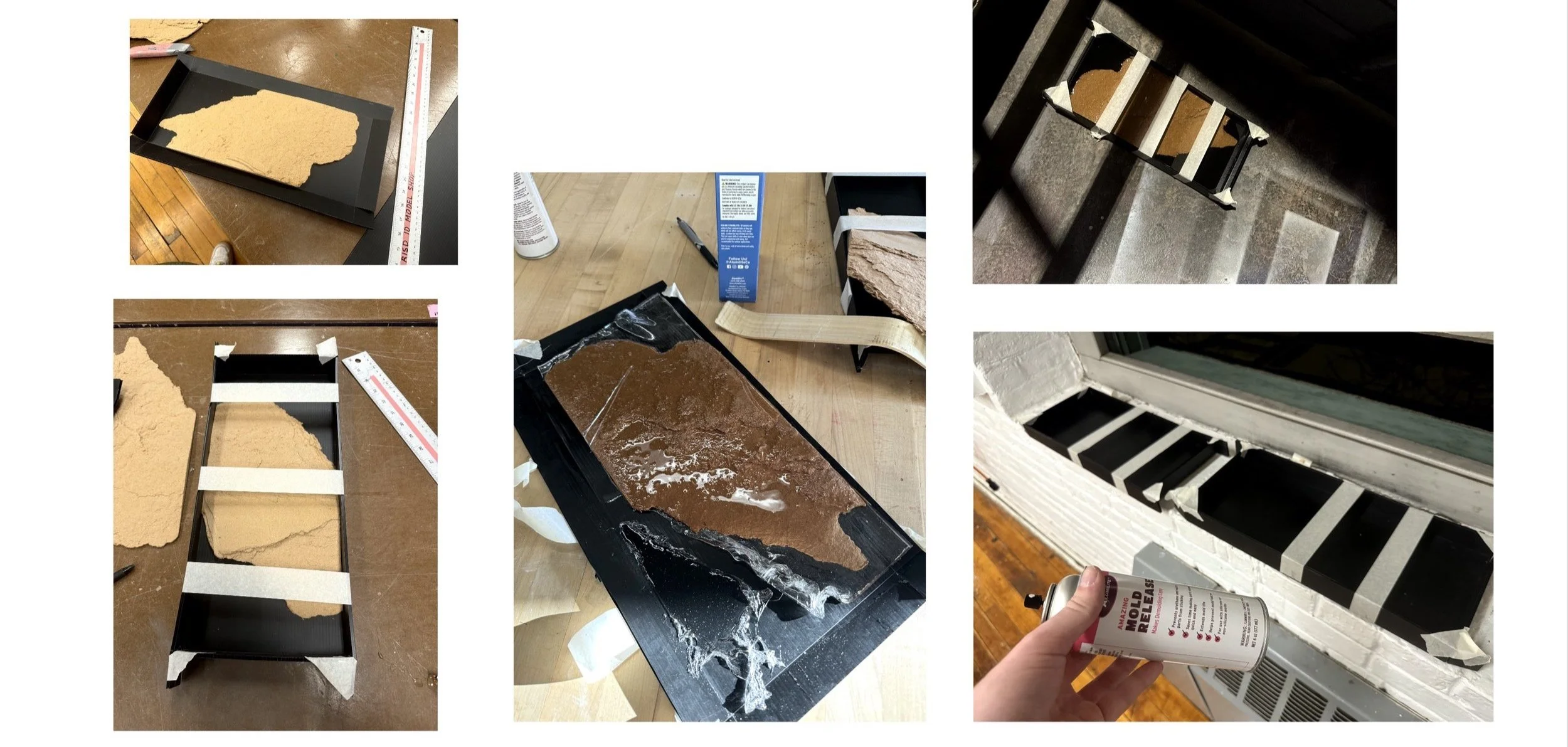

Prototype 1

For my first piece, I ran into more failures than I may have expected. My Initial intention was to show the highlight the rigid texture of the ripped plywood. Utilizing it’s previous shape, I formed an epoxy around it, highlighting the form in a clear mold.

This did not go as planned, and after attempting to epoxy two similar boards, the cast remained soft. Meanwhile, the second piece was mistaken for rubbish and thrown away. Unfortunate, yet educational.

Prototype 2

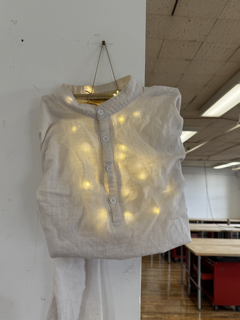

In this second prototype, I used a spare shirt I, wood scrap, hemp cord, and string lights. Drawing the rustic and raw light asthetic, I was happy with it, yet still wanted to push the bounds as my peers, guest critics, and I felt there was more to offer. Could I elevate detritus to a fine art?

Prototype 3

For my last prototype, I wanted to display the crevise found in this solid block of wood. It must have been tossed for such a thing.

The process was straight-forward: I carefully cross-cut the piece, into frames, drilling 5/8” skrews to the back board. Afterwards, I drilled a very tight sectional into the side of the board and installed two brass wires to serve as legs for a shoes stand, or as handles for a hanging magazine stand.